Fasta Pasta - online meetings speed custom gearbox design

Renold Gears has designed a bespoke gearbox for Swiss food processing equipment manufacturer, Bűhler, in record time with just three online meetings between the customer's engineers, and Renold's engineers in both Switzerland and the UK. With gearbox design and manufacture at one location at Renold's factory in Rochdale, the online meetings, using TeamViewer, cut costs and reduced the time to design a custom solution that met the customer's requirements.

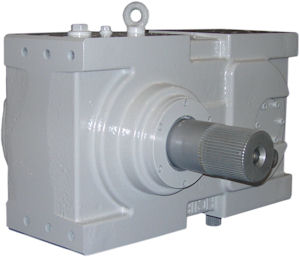

The new custom gearbox, for a pasta making machine, was a multiple input bevel-helical unit that had to fit within very tight space constraints and meet demanding weight limits. To achieve this Renold's engineers had to use the latest finite element analysis and 3D modelling software to reduce the thickness of the gearbox casing without compromising its structural integrity.

The new design was based on Renold Gears' heavy-duty HC Series helical and bevel-helical gear units with case hardened and profile ground gears for high torque applications. Using TeamViewer allowed both sets of engineers to make real time changes online and see the results. It also significantly reduced the time that physical meetings would have required, speeding up the decision making process and the time the project took to reach sign off.

For over 100 years, Bűhler has been developing commercial production lines for making fine pasta. Experience, knowledge, Swiss precision and a profound understanding of market needs have made Bűhler a world-leading technology group in the development, design and manufacture of industrial scale pasta lines.

Contact us now for more information, or to discuss your own requirements: