Full Range of Air Preheater Drives has All Options Covered

|  |

Renold Gears designs and manufactures a complete range of specialist drive solutions for the huge air preheaters (APH) found at gas, oil and coal fired power stations. These air preheaters are very large fans that preheat the combustion air before it enters the boiler to improve its thermal efficiency. This is achieved by recycling the hot flue gas as it leaves the furnace, heating the elements of the fan as it is turned slowly by an APH gearbox. This heat is then transferred to the air as it enters the boiler.

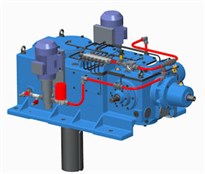

Renold provides solutions for all the different types of air preheaters including new designs for OEMs or replacement drives to power stations. This includes multiple input helical worm and bevel-helical gear drive options with configurations to suit centrally or peripherally driven air preheaters.

The multiple input helical-worm-worm option can be supplied with a hollow bore output for direct mount to the drive shaft, or it can be supplied with an optional rubber-in-compression coupling from Renold Hi-Tec Couplings. The gearbox can be direct mounted to multiple prime movers including AC, DC or air motors.

The bevel helical solution is a multi-stage design with the option of a solid output shaft, either vertically up or down, and with provision for multiple inputs and integrated sprag clutch holdbacks to prevent drive reversal. The drives include a self-contained lubrication system. They can be either gear pump or electric motor driven and can be supplied with separately mounted gear motors for barring. The main motor is driven by a fluid coupling for soft starts. Both options can be manufactured in a range of sizes to suit power stations from 200 to 1200mw. Different torque requirements are dependent on the size of the power station.

Units can be manufactured for centrally driven air preheaters, including worm and helical gearing configurations that can be designed as drop-in replacements for originally supplied units, or designed to the OEM's specification for new applications. A central design has a solid output shaft and mounts directly on to the main rotor shaft of the APH and is secured by means of a shrink disc.

Alternatively solutions can be supplied for peripherally driven air preheaters. A peripheral drive is mounted on to the extremity of the APH and is supplied with a solid output shaft on to which a spur gear is mounted that drives the APH via an externally mounted girth-ring gear.

Contact us for more information: